Atomic Layer Deposition Creates Advanced Eco-Friendly Vehicle Materials

Atomic Layer Deposition (ALD) is a manufacturing method at the atomic and near-atomic scale. Since its invention in the 1970s, ALD has been industrially applied in fields such as displays, semiconductors, and solar cells. Professor Rong Chen from Huazhong University of Science and Technology and her team have provided a detailed introduction to the latest progress of ALD in the fields of catalysis and energy materials.

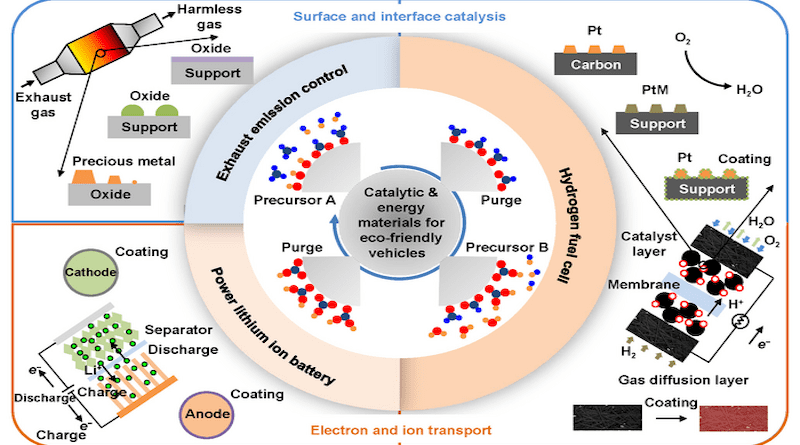

Publishing in the journal International Journal of Extreme Manufacturing (IF:10.036), the team led by researchers based at the State Key Laboratory of Intelligent Manufacturing Equipment and Technology highlighted the latest progress of ALD technology in the application of exhaust catalytic converters, lithium-ion batteries, and hydrogen fuel cells.

By depositing single atoms or molecules layer by layer, ALD allows for precise control of film thickness and composition, which can improve the performance and stability of catalysis and energy materials. The team introduced the application progress of ALD in exhaust gas catalysts, lithium-ion batteries, and hydrogen fuel cells, as well as the latest advancements in large-scale ALD equipment.

The lead researcher, Professor Rong Chen, commented, “Low-temperature activity of exhaust gas catalysts is key to eliminating pollutants during the cold start phase, while high-temperature stability of the catalysts determines their lifespan under working conditions. ALD has been used to prepare loaded noble metal catalysts, precisely control the size of the noble metal and the interaction between the noble metal and the carrier. To improve the high-temperature stability of the noble metal, ALD has been used to construct a confinement structure for the noble metal.” Through the application of ALD technology, the interfacial properties of catalysis and energy materials can be precisely controlled, thereby improving their performance and stability.

The cycling stability and safety issues of lithium-ion batteries are closely related to the failure of battery materials. The use of ALD to prepare nanocoatings on cathode, anode, and separator materials can not only improve the electrochemical stability of the materials but also ensure the transmission of electrons and ions. The ultra-thin coatings on typical positive electrode materials such as lithium iron phosphate, high-nickel ternary, and nickel-manganese spinel improve the structural stability of the materials and suppress the side reactions of the materials and electrolyte during charge and discharge cycles.

First author Assoc. Prof. Xiao Liu said, “Hydrogen fuel cells have high costs and short lifetimes, which are major obstacles to their large-scale commercial use. However, ALD can help overcome these issues by preparing size-controlled and highly dispersed Pt catalysts. This not only increases the utilization of Pt atoms but also reduces the mass transport resistance of O2in the membrane electrode catalyst layer.”

ALD is used to modify the Pt catalyst and conductive carrier, enhancing the intrinsic activity and stability of the catalyst. At the device level, ALD is used to modify the surface of the catalyst layer, gas diffusion layer, and proton exchange membrane, improving the device’s mass transfer performance and durability.

Developing efficient and large-scale ALD equipment is crucial for industrial applications to meet the ton-level material demand in the catalysis and energy material fields. However, particle aggregation during the ALD process can cause issues with slow and uneven coating. Recent research focuses on developing large-volume chambers, coupled particle coating equipment, and spatially separated continuous coating equipment based on the early reported fluidized bed and rotating bed powder ALD devices.

Prof. Rong Chen said: “Despite the use of ALD to improve catalytic and energy materials, challenges remain for its large-scale application in the automotive industry. These include the development of cost-effective precursors, the evaluation of ALD-modified material performance at the device level, and the challenge of large-scale and efficient ALD coating of catalytic and energy materials. Addressing these challenges will require further research in various areas, including precursor development, performance evaluation, and equipment design.”