Making Hydrogen Fuel Anywhere: ONR Tests Prototype To Power Marines In Expeditionary Environments

U.S. Marines often operate in extremely harsh environments — including remote islands, hot deserts, rugged mountains and frozen, barren landscapes.

While these warfighters employ sophisticated, technologically superior equipment and weaponry in the field, such tools need large amounts of fuel and energy to perform — a tough demand in austere operating environments.

To address this, the Office of Naval Research (ONR) Global TechSolutions program is sponsoring efforts by the Massachusetts Institute of Technology (MIT) Lincoln Laboratory to convert aluminum into hydrogen fuel, which could potentially serve as a portable, readily available power source.

TechSolutions is ONR Global’s rapid-response science and technology program that develops prototype technologies to address problems voiced by Sailors and Marines, typically within approximately 12 months from project initiation.

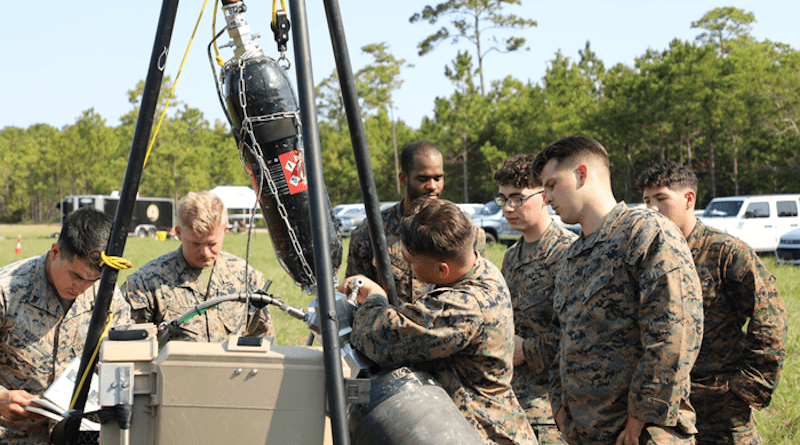

Marines recently saw a demonstration of a TechSolutions project that involved a fuel-generation prototype device — called the hydrogen tactical refueling point (H-TaRP) — at Marine Corps Base Camp Lejeune, North Carolina. Part of this demonstration included Marines learning how to assemble the H-TaRP as well as receiving a static demonstration of how the H-TaRP equipment works. The Marines learned how hydrogen can be produced with H-TaRP.

“ONR Global TechSolutions got involved with H-TaRP when the Marines expressed their desire to get fuel in an expeditionary environment,” said Jason Payne, director of the ONR Global TechSolutions program. “TechSolutions took the concept and reached out to our network of providers to create that solution, and MIT was chosen through a competitive process. TechSolutions provided the resources needed to develop a proof-of-concept prototype.”

When Marines are in the field, their energy options are normally either petroleum- or battery-based. Batteries are effective but can weigh a lot and must be constantly recharged via a power source.

H-TaRP — which comprises an aluminum dispenser, reactor vessel, water cooling system and a control system manifold to fill an H2 tank — can address these energy issues with a lighter, agile system that will ultimately lighten the load for Marines.

“H-TaRP’s purpose is to eliminate the need for diesel fuel transport and battery charging by being able to use locally available resources to produce hydrogen fuel for all sorts of vehicles,” said Erik Limpacher, leader of the Energy Systems Group at MIT Lincoln Laboratory.

Using simple chemistry, MIT researchers exploited the reaction of aluminum mixed with water to generate hydrogen gas. Any form of water works in the chemical reaction: salty ocean water, river water, even urine. This enables H-TaRP to potentially be used in many different environments.

Additionally, since steam is leftover after the hydrogen fuel creation process, it’s available to be distilled and used for drinking and hydration.

This model of energy logistics has many benefits over traditional liquid fuels. Utilizing this special aluminum as a precursor to hydrogen fuel allows for the storage and transportation of an inert solid instead of liquid fuel or pressurized gas, which greatly improves safety. Hydrogen gas is also compatible with fuel cell usage, which does not generate the noise and heat signature associated with internal combustion engines.

“Looking ahead to the 21st-century battlefield, Marines will be separated from their logistics many times,” said Maj. Steve Simmons, who commanded Marines during the Camp Lejeune demo. “We anticipate our logistic lines will be too long to be effective to provide immediate support to Marines. Looking at the battlefields for the next 100 years, we see the need for readily available resources to be converted into natural energy.”

During the demo, junior infantry Marines received a brief tutorial on assembling the H-TaRP system and fire teams of up to four warfighters practiced putting it together a couple of times. After one iteration, they assembled the system in just 13 minutes — showing the H-TaRP device could be deployed quickly with minimal training. The Marines also provided feedback and guidance and showed the MIT engineers a two-man assembly process for their system.

Future plans for H-TaRP involve extended operation and high pressure H2 generation, as well as making the device 50% smaller, aligning it with the Marine Corps commandant’s vision of fielding Marine units with greater mobility and agility.