Highly Transparent Electrodes For Deep-UV Light Emitting Diode Applications

Scientists from Tokyo Metropolitan University have developed a new electrode material for deep-ultraviolet (DUV) light-emitting diode applications. They used a cutting-edge deposition technique to form thin films of an alloy of tin oxide and germanium oxide with added tantalum, finding that they exhibit excellent electrical conductivity and unprecedented transparency for DUV light. The new electrodes promise to impact industry, as the same wavelengths are used for sterilization processes and the manufacture of microchips.

Deep ultraviolet (DUV) light, with a wavelength of 200 to 300 nanometers, has some very important roles to play in industry and society. It can be used to sterilize water and surfaces by inactivating bacteria and viruses and for curing adhesives which harden on exposure to DUV light. Crucially, it is used in the manufacture of the most advanced semiconducting chips and devices.

With adoption of DUV technology only getting bigger and bigger, scientists are keen to develop deep UV light-emitting diode (LED) devices, tapping the unparalleled energy efficiency, scalability, and compactness of LED sources. LEDs feature light-emitting layers of material sandwiched between a pair of transparent electrodes, which have to let the light through as well as conduct electricity. Though such LEDs exist, existing electrode materials are yet to combine conductivity with optimal transparency; they still absorb a significant proportion of DUV light.

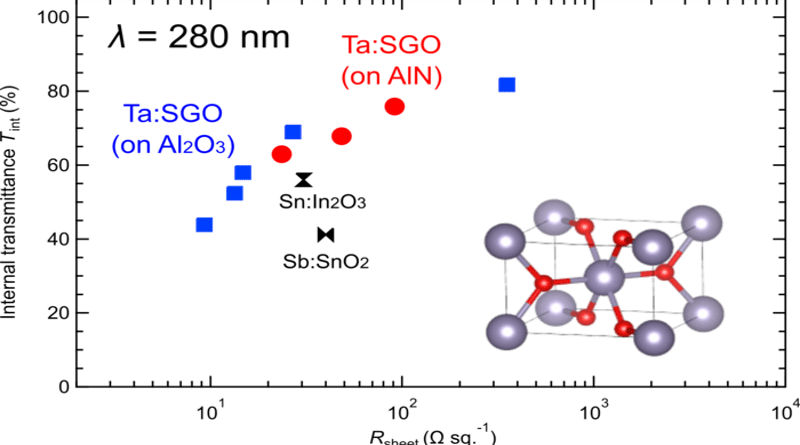

Now, a team led by Professor Yasushi Hirose of Tokyo Metropolitan University have developed a thin film transparent electrode with excellent conductivity and, crucially, unprecedented transparency for deep UV light. They combined a widely used ingredient of transparent electrodes, tin oxide, and mixed it together with germanium oxide, a material with a similar crystalline structure but better transparency. These two materials are usually not soluble in each other, so the team used pulsed laser deposition, a method that allows insoluble materials to be deposited together without them spontaneously separating out into distinct regions. They showed that deep UV transmittance (the proportion of light let through) gets better and better with more germanium oxide addition. By adding some tantalum, they also improved the electrical conductivity of the films.

By optimizing the recipe, the films that were produced showed low resistivity and some of the best transmittance of DUV light out of all known electrode materials, including the most common transparent electrode material, indium tin oxide (ITO). Importantly, they showed that the films could be formed on aluminum nitride (AlN) substrates by using a crystalline “seed” layer of tin oxide. Aluminum nitride is a key material in deep UV LEDs; the compatibility of the team’s newly designed tantalum tin germanium oxide (Ta:SGO) films with AlN makes their work extremely promising for real-world applications in the next generation of light sources for chip manufacture, and beyond