Getting It Down Cold: Tackling Challenges Of Storing Liquefied Hydrogen

Although hydrogen is projected to replace fossil fuels in the near future, there are many unresolved technical issues regarding its storage and transportation. In recent studies at Pusan National University, Korea, Prof Jae-Myung Lee’s group has found promising solutions to two important problems: steel embrittlement and insufficient insulation. Their findings will help us repurpose existing liquefied natural gas containers for transporting hydrogen overseas, thus laying the foundations for a fully-fledged hydrogen economy.

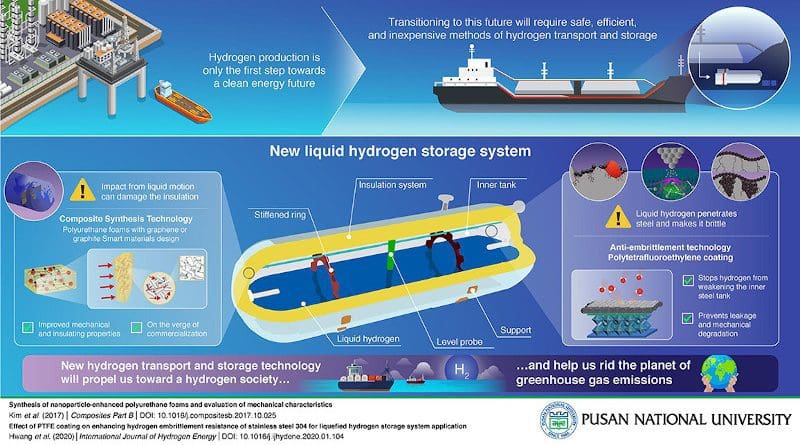

Hydrogen is globally viewed as one of the best alternatives to fossil fuels and is projected to become the main way of storing energy by 2030. But, if we are to make these future hydrogen societies a reality, we need not only inexpensive methods to produce hydrogen, but also efficient and safe ways to transport it overseas. The issue of hydrogen storage and transportation is not an easy one; liquified hydrogen has to be kept at −253°C, which entails a variety of technical problems to which no one has found definitive solutions.

Motivated by this challenge, Professor Jae-Myung Lee’s research group at Pusan National University, Korea, have been conducting research to find commercially feasible ways to store and transport liquefied hydrogen. Prof. Lee is actively working with over 20 researchers to replace liquefied natural gas technology and make existing systems suitable for liquefied hydrogen. In his group’s most recent studies, published in the International Journal of Hydrogen Energy and Composites Part B: Engineering, they propose innovative solutions to two of the main problems that make transporting hydrogen in steel containers difficult: “embrittlement” and insulation.

Hydrogen embrittlement is a well-known phenomenon by which hydrogen atoms penetrate the inner walls of steel containers and cause the appearance and enlargement of cracks, which can result in leakage accidents. To tackle this issue, Prof. Lee’s group has developed a practical solution in the form of a polytetrafluoroethylene (PTFE) coating. This polymer prevents hydrogen from penetrating the steel and thereby reduces embrittlement on the inner walls of the containers.

On the other hand, the problem of insulation stems from the fact that existing liquefied natural gas containers are not suitable for carrying liquefied hydrogen unless the thickness of their insulating polyurethane foam is substantially increased. Moreover, increasing the insulation of polyurethane materials generally comes at the cost of material strength, making it particularly difficult to improve upon existing technology. To address this issue, Prof. Lee’s group has developed advanced theoretical models and novel concepts in polyurethane foam insulation, including foam enhancement with graphene nanoparticles.

Excited about their results, Prof. Lee remarks, “Our best additives improved both the strength and insulation performance of polyurethane foams by 38% and 8%, respectively. In addition, our predictive models for materials design can greatly reduce the initial investment for developing novel insulation materials in terms of time and cost.”

Overall, the research efforts by Prof. Lee’s group are getting us closer to the transition into a hydrogen economy. With eyes on the future, Prof. Lee concludes, “Efficient and economical hydrogen storage technology is widely recognized as the backbone of the realization of a hydrogen economy. Our work will contribute to the establishment of a value chain for the transport, storage, and utilization of hydrogen and help us create a cleaner environment for everyone to live in.”