The Future Of Heat Pumps – Analysis

Physically, heat energy is present whenever the temperature is above absolute zero (at 0 Kelvin or ‐273 °C). Heat pumps utilize a coolant with a boiling point as low as -22 to -40 °F (-30 to -40 °C). It extracts heat from the outdoors, even during the winter, and transfers this heat indoors to warm the building. In the summer, some heat pumps work in reverse, effectively cooling the building by expelling heat outside.

A heat pump uses technology similar to that found in a refrigerator or an air conditioner. It extracts heat from a source, such as the surrounding air, geothermal energy stored in the ground, or nearby sources of water or waste heat from a factory. It then amplifies and transfers the heat to where it is needed. Because most of the heat is transferred rather than generated, heat pumps are far more efficient than conventional heating technologies such as boilers or electric heaters and can be cheaper to run. The output of energy in the form of heat is normally several times greater than that required to power the heat pump, normally in the form of electricity.

A heat pump is a device that pulls the energy out of air for the purpose of either heating or cooling a space by transferring thermal energy using a refrigeration cycle. This process is known as space conditioning. Heat pumps operate as a heat engine in reverse, as they do work from an input of electricity to push heat from a cold place to a warm place. This would seemingly violate the Second law of thermodynamics, but the key reason it doesn’t is because this heat transfer is not spontaneous; it requires an input of energy to do so. For home heating, a heat pump extracts heat from outside air, heats the warm air up even more, and transfers it indoors. For home cooling, a heat pump reverses this process and heat is extracted from the indoor air and expelled to the outside, just like a refrigerator or air conditioner, thereby making the inside air cooler.

As they transfer heat rather than generating heat, they are more energy-efficient than other ways of heating or cooling a home. A gaseous refrigerant is compressed so its temperature rises. When operating as a heater in cold weather, the warmed gas flows to a heat exchanger in the indoor space where some of its thermal energy is transferred to that indoor space, causing the gas to condense to its liquid state. The liquified refrigerant flows to a heat exchanger in the outdoor space where the pressure falls, the liquid evaporates and the temperature of the gas falls. It is now colder than the temperature of the outdoor space being used as a heat source. It can again take up energy from the heat source, be compressed and repeat the cycle.

The heat pump itself consists of a compressor, which moves a refrigerant through a refrigeration cycle, and a heat exchanger, which extracts heat from the source. The heat is then passed on to a heat sink through another heat exchanger. In buildings, the heat is delivered using either forced air or hydronic systems such as radiators or under‐floor heating. Heat pumps can be connected to a tank to produce sanitary hot water or provide flexibility in hydronic systems. Many of the heat pumps can also provide space cooling in summer in addition to meeting space heating needs in winter. In industry, heat pumps are used to deliver hot air, water or steam, or to directly heat materials. Large‐scale heat pumps in commercial or industrial applications or in district heating networks require higher input temperatures than in residential applications, which can be sourced from the waste heat of industrial processes, data centres or wastewater.

Air source heat pumps are the most common models, while other types include ground source heat pumps, water source heat pumps and exhaust air heat pumps. Large-scale heat pumps are also used in district heating systems.

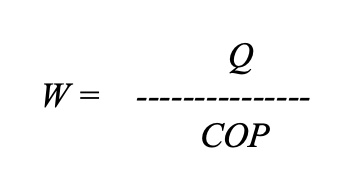

The efficiency of a heat pump is expressed as a coefficient of performance (COP), or seasonal coefficient of performance (SCOP). It is expressed by the ratio of heat output to the work needed to be input. Essentially, this value is how much cooling or heating is being done for a person’s dollar (electricity isn’t free after all). This ratio is represented by the equation:

Where;

W is the work performed on the working fluid by the heat pump’s compressor.

Q is the heat transferred from the lower-temperature reservoir to the higher-temperature reservoir.

COP is the instantaneous coefficient of performance for the heat pump at the temperatures prevailing in the reservoirs at one instant.

The higher the number, the more efficient a heat pump is; because it requires less work to do a certain amount of heat transfer. However, there is a limit set by the laws of entropy and the second law of thermodynamics. For example, the coefficient of performance (COP) for a typical household heat pump is around four, i.e. the energy output is four times greater than the electrical energy used to run it. This makes current models 3‐5 times more energy efficient than gas boilers. Heat pumps can be combined with other heating systems, commonly gas, in hybrid configurations.

Around 10 percent of space heating needs globally were met by heat pumps in 2021, but the pace of installation is growing rapidly. The share of heat pumps is comparable to that of fuel oil for heating and of other forms of electric heating but lower than the over 40 percent of heating reliant on gas heating and the 15 percent reliant on district heating. Because of their high efficiency and the increasing share of fossil-free sources in electrical grids, heat pumps are playing a key role in climate change mitigation. Consuming 1 kWh of electricity, they can transfer 1 to 4.5 kWh of thermal energy into a building. The carbon footprint of heat pumps depends on how electricity is generated, but they usually reduce emissions. Heat pumps could satisfy over 80 percent of global space and water heating needs with a lower carbon footprint than gas-fired condensing boilers.

In some countries, heat pumps are already the largest source of heating. In Norway, 60 percent of buildings are equipped with heat pumps, with Sweden and Finland at over 40 percent, undercutting the argument that heat pumps are unsuitable for cold climates. Global sales grew by nearly 15 percent in 2021, double the average of the last decade. Growth in the European Union was around 35 percent, and is slated to accelerate further in light of the energy crisis, with sales in the first half of 2022 roughly double over the same period last year in Poland, the Netherlands, Italy and Austria. China continues to be the largest market for new sales, while North America has the largest number of homes with heat pumps today. Together, these regions, along with Japan and Korea, are also major manufacturing hubs, home to the industry’s largest players.

Accelerating the deployment of heat pumps hinges on overcoming a number of barriers, some of which are universal while others are specific to particular countries or regions. For heat pumps in buildings these barriers include both barriers on the demand side – cost and other market hurdles to customer adoption of heat pumps – and the supply side – practical constraints on expanding manufacturing and the availability of sufficient numbers of trained installers.

Heat pumps, powered by low‐emissions electricity, are the central technology in the global transition to secure and sustainable heating.Heat pumps currently available on the market are three‐to‐five times more energy efficient than natural gas boilers. They reduce households’ exposure to fossil fuel price spikes, which has been made all the more urgent by the ongoing global energy crisis. Over one‐sixth of global natural gas demand is for heating in buildings – in the European Union, this number is one‐third. Many heat pumps can provide cooling, too, which eliminates the need for a separate air conditioner for the 2.6 billion people who will live in regions requiring heating and cooling by 2050. Heating in buildings is responsible for 4 gigatonnes (Gt) of CO2 emissions annually – 10 percent of global emissions. Installing heat pumps instead of a fossil‐fuel‐based boilers significantly reduces greenhouse gas emissions in all major heating markets, even with the current electricity generation mix— an advantage that will increase further as electricity systems decarbonise.

Heat pumps can also address heating needs in industry and district heating.Large heat pumps can provide heat up to 140‐160 o C today, with higher temperatures possible through innovation and improved designs. The most common industrial heat pumps today provide lower temperature heat. The paper, food and chemicals industries have the largest near‐ term opportunities, with nearly 30percent of their combined heating needs able to be addressed by heat pumps. In Europe alone, 15 GW of heat pumps could be installed in 3 000 facilities in these three sectors, which have been hit hard by recent rises in natural gas prices.

Accelerating deployment of heat pumps in line with national climate targets is well within reach but requires further efforts from policy makers and industry.The market growth in heat pumps needed this decade to hit national climate targets is not as steep as the expansion we have already seen in solar PV and electric vehicles, although there would need to be a further acceleration to get on track for the IEA’s Net Zero Emissions by 2050 Scenario. The additional upfront investment required is sizable, reaching USD 160 billion annually by 2030, but these incremental costs are outweighed by economy‐wide savings on fuel, especially if today’s high prices persist. Governments and industry have vital roles to play to address persistent market barriers and enable heat pumps to play their full part in addressing today’s most pressing issues – energy security, energy affordability, and rapid reductions in emissions.

Switching to heat pumps cuts emissions of greenhouse gases and helps improve air quality.Accelerated deployment of heat pumps, in line with national climate targets, can reduce global CO2 emissions by half a gigatonne already by 2030. However, unintended leaks of F‐gas refrigerants – potent greenhouse gases – can decrease their positive climate impacts. With today’s refrigerants, heat pumps still reduce greenhouse gas emissions by at least 20percent compared with a gas boiler, even when running on emissions‐intensive electricity. This reduction can be as large as 80percent in countries with cleaner electricity. Global emissions of major air pollutants caused by combustion heating in buildings also drop, particularly from coal in China, while other hazards associated with heating by fuel combustion diminish.

The expansion of heat pump manufacturing and installations to meet rising demand would create more jobs. Global employment in heat pump supply nearly triples to over 1.3 million workers to 2030. Jobs in installation grow the most, with growth also in maintenance and manufacturing, providing numerous opportunities, especially for medium‐ skilled workers.

Accelerating the take‐up of heat pumps requires overcoming a number of barriers. Chief among them are the higher upfront cost of buying and installing the devices relative to other heating options; other non‐cost deterrents to consumer adoption; manufacturing constraints; and potential shortages of qualified installers. Concerted action by governments, in partnership with the heat pump industry, is needed to address these hurdles and achieve higher rates of deployment.

Long‐term policy consistency and regulatory certainty, together with targeted action to strengthen supply chains, remain critical for manufacturers as they consider where to expand their operations. In particular, regulations on F‐gases must balance the need to limit refrigerant emissions with cost, safety, energy efficiency and supply chain considerations.