Accelerating Military Innovation: Lessons From China And Israel – Analysis

By NDU Press

By George M. Dougherty*

The U.S. military’s technological advantage is under threat. Since the end of the Cold War, the military has been largely occupied with relatively low-tech counterterrorism and counterinsurgency conflicts against non-peer adversaries. Much U.S. defense research and development (R&D) during that time focused on delivering incremental innovations to address capability gaps in existing systems and warfighting concepts. As a result, many of today’s frontline systems are upgraded versions of those used in the Gulf War almost 30 years ago.1 Meanwhile, Great Power competitors including China and Russia have worked to quickly close the technology gap with the United States.2 China, in particular, possessed almost no modern-generation military systems prior to 2000.3 Nonetheless, it has modernized so rapidly that in 2018 the Vice Chairman of the U.S. Joint Chiefs of Staff warned that China could achieve its goal of equaling U.S. military technological prowess by 2020 and surpass it by the 2030s if Washington does not react quickly.4

Department of Defense (DOD) and military Service leaders are making strategic-level changes to accelerate innovation. Examples include the establishment of the Office of the Under Secretary of Defense for Research and Engineering, within the Office of the Secretary of Defense; the creation of the U.S. Army Futures Command; and the publication of an ambitious new Air Force Science and Technology Strategy.5 These changes feature a renewed emphasis on promoting disruptive innovations that can deliver leap-ahead advances in military capability, changing the character of military operations and providing sustained advantage for U.S. forces. DOD and the Services are seeking to identify and implement the supporting acquisition practices that can accelerate disruptive innovation.6

The United States has been in similar situations before. When Japanese companies made competitive gains against U.S. industrial firms in the 1980s and 1990s, the United States reacted in part by identifying and adapting the key practices, such as Kaizen and Total Quality Management, that were enabling the outperformance of Japanese industry. Are similar practices helping to enable the most successful U.S. global peers in military innovation? Could some of these practices be adapted within the U.S. defense establishment?

Two national case studies are particularly relevant. First, China’s rapid technological rise is the main impetus behind the U.S. focus on military innovation. It has achieved its remarkable gains despite military budgets less than half the size of those of the United States.7 Absorption, even theft, of foreign technologies has been part of its strategy, but is only part of a much more complex picture.8 As the most direct peer U.S. competitor, with a similarly large and complex defense enterprise, China’s practices could be applicable to U.S. defense innovation.

Second, Israel is remarkable for its ability to produce maximum military innovation with limited resources. Its defense budget is less than one-thirtieth that of the United States. Nonetheless, the ability of the tiny “startup nation” to rapidly and affordably bring unique capabilities to the field is leading the United States to import some of its novel defense products, such as the Iron Dome missile defense system and the Trophy active defense system for armored vehicles. While not a peer in terms of size, Israel is also a free-market democracy with a private-sector defense innovation base and a commitment to military technological superiority. Practices that enable its efficiency in military innovation could be highly transferable to the U.S. defense sector.

The United States is neither a single-party authoritarian state nor a small country with universal military service. Many Chinese and Israeli practices may not be relevant in the U.S. context. In both cases, this analysis focuses on transferable best practices that could be adapted within the context of the U.S. system by leaders in the U.S. defense establishment.

China: Effectively Managing Complex Military-Technical Transformation

The Chinese defense-industrial system was built in a national system governed by centralized top-down planning. Due partly to this legacy, it exhibits several structural weaknesses that inhibit innovation, including corruption,9 the entrenched monopoly power of state-owned defense firms,10 weak institutions and management systems at the corporate or system integration level,11 and an immature and fragmented innovative research ecosystem.12 Despite its rapid modernization, China has not yet shown that its system can generate its own disruptive military technological innovations.13 However, it has shown great effectiveness in translating new technologies into military products and quickly fielding them across a large military enterprise, areas where the less centralized U.S. system has sometimes had difficulty. China’s legacy of structured planning provides strengths, particularly in cross-sector coordination and the ability to link China’s military strategy with its supporting military R&D and acquisition activities.14

Three transferable practices have been important to the speed and effectiveness of Chinese military modernization. These are the Chinese approaches to synchronized hierarchical strategic planning for defense R&D, a powerful technology-enabled methodology for cross-enterprise design and decisionmaking, and the systematic use of full-scale platforms for prototyping and experimentation.

Synchronized Hierarchical Strategic Planning. China’s military acquisition activities are guided by a hierarchical sequence of formal plans that are published on a regular schedule. The Weapons and Equipment Development Strategy (WEDS) is the top-level acquisition strategy document. It starts with an analysis of China’s national security environment, identifies military strategic capability needs for future conflicts, assesses strengths and gaps in existing armaments, and establishes R&D priorities.15 It equates roughly to a combination of the U.S. National Defense Strategy, studies by the DOD Office of Net Assessment, and a DOD-wide acquisition strategy. The WEDS covers a planning horizon of 20 years, with a new WEDS published at the start of every decade.16

The Long-Term Weapons and Equipment Construction Plan (LWECP) defines the acquisition strategies across the entire defense establishment to address the gaps identified in the WEDS.17 It covers a planning horizon of 10 years. Supporting medium- and short-term plans are then created that describe the resource allocations and programmatic aspects for the supporting defense acquisition programs.

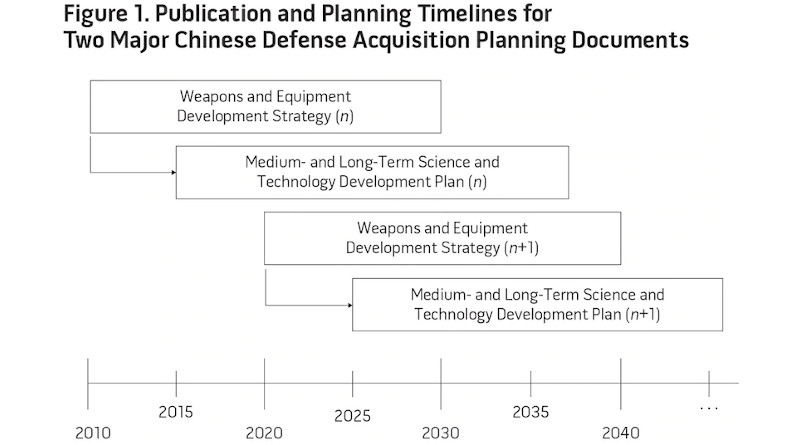

Defense science and technology (S&T) efforts, focused on longer term innovation, are guided by the Defense Medium- and Long-Term S&T Development Plan (MLDP). The MLDP is published at the midpoint of each decade, 5 years following the WEDS, with a planning horizon of 15 years.18 The relationship between the publication dates and planning horizons of the WEDS and MLDP are illustrated in figure 1. The LWECP and other plans synchronize within this same regular cycle.

The MLDP is developed by the Science and Technology Committee (STC) via a collaborative effort among the People’s Liberation Army (PLA), civilian defense industry officials, and S&T experts.19 The STC includes over a dozen active PLA generals, many luminaries of the Chinese defense technology sector, and more than 40 technical panels engaging an estimated 1,000 technology specialists from across the defense S&T landscape.20 The STC was historically the largest body within the Chinese General Armaments Department (GAD), which manages all military acquisition, and its director, equivalent to a U.S. four-star general, was equal in rank to the overall head of the GAD.21 In 2015, the STC was further elevated to report directly to the Central Military Commission, which is similar to the U.S. Secretary of Defense and Joint Chiefs of Staff, making it coequal with the GAD.22 The STC leadership combines military and technical expertise. The STC director as of 2015, General Liu Guozhi, holds a Ph.D. in physics, spent much of his career in R&D, and is a member of the Chinese Academy of Sciences.23

This system of regularly updated hierarchical plans with clear interrelationships rationalizes the demand for new military R&D. It helps provide the stability needed for long-term research and reduces the need for new innovations to compete against sustainment of the current force for priority and resources.

In addition, the plans employ a technological generation–based planning framework. The United States categorizes modern fighter aircraft as fourth or fifth generation, with the fifth generation defined by the incorporation of characteristic technologies such as stealth and advanced sensor fusion and data networking. Chinese planners apply a similar construct to define technological generations for all categories of military systems, from aircraft to ground vehicles to information systems.24 The expected transitions to future generations are projected on timelines in the strategic plans, enabling different parts of the defense enterprise to plan technology investments targeting those transition dates with confidence that the necessary funding, complementary technologies, and operational military transition activities have been aligned.

A Powerful Technology-Enabled Methodology for Cross-Enterprise Design and Decisionmaking. Chinese R&D strategic plans are developed with the help of a powerful problem-solving and design methodology. Solutions to large-scale, real-world planning problems can be challenging to design. There are too many variables, and while some aspects may be subject to quantitative analysis, others may rely on qualitative expert judgment. In 1990, Chinese defense technology leader Qian Xuesen proposed a new approach called meta-synthetic engineering as a framework for designing optimal solutions to such problems.25 Qian’s primary application was military-technical planning, and the approach has since become widespread in the Chinese defense sector, as well as in additional fields such as economic and industrial planning.26

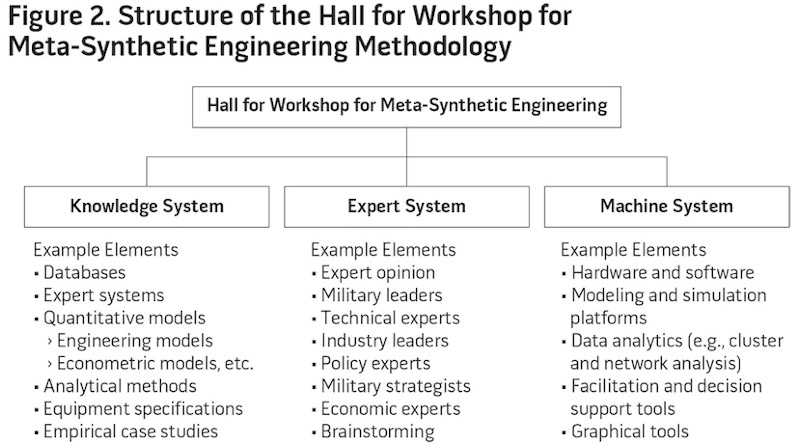

The practical implementation of meta-synthetic engineering is a process known as the Hall for Workshop for Meta-Synthetic Engineering (HWMSE). In essence, this is a workshop involving experts from the relevant disciplines, augmented by software model libraries and databases of relevant quantitative data, and a simulation engine that can integrate the expert judgment with the quantitative data to produce detailed projected outcomes.27 These three parts are labeled the expert system, the knowledge system, and the machine system, respectively, as illustrated in figure 2.

The methodology has become highly developed, and modern defense applications can add multiple layers of complexity within this basic architecture.28 Purpose-built software tools have been developed to support the machine system, using iteration and methods such as network and cluster analysis to help merge the qualitative and quantitative analyses and converge on solutions.29 The HWMSE process has become institutionalized within China, and customized facilities have been constructed to host workshops within major agencies and institutes.30

Full-Scale Prototyping Platforms. Chinese defense R&D teaching emphasizes the importance of prototyping as a critical element in defense technology development. The Chinese military R&D process specifies at least three different categories of system-level prototypes and demonstrations, aligned to different stages of technology readiness as defined by technology readiness level (TRL):31

- yuanli yangji (theoretical prototype), TRL 4

- yanshi yangji (demonstration prototype), TRL 5

- gongcheng yangji (system-level engineering prototype), TRL 6–7.

The Chinese emphasis on full-scale prototyping may be observed clearly in naval technology development. Several large PLA Navy ships are dedicated as full-scale prototyping and experimentation platforms. Two 6,000-ton vessels known as the Type 909 Dahua-class are dedicated to full-scale prototyping and testing.32 These ships have been used for trials of developmental missile systems, radars, and other systems that later appeared as equipment on front-line combat ships.33 There is also a 3,800-ton Type 032 Qing-class submarine that is dedicated to trials of new undersea technologies, such as submarine-launched missile systems.34 In addition, other full-scale vessels have been dedicated to experimentation and prototyping activities. A 7,000-ton Type 072 III landing ship was recently observed in use as a full-scale at-sea test platform for what may be a prototype electromagnetic railgun weapon.35 The practice may also extend to the experimental repurposing of aging vessels before their retirement, such as an older frigate that was fitted with banks of 120-millimeter rocket launchers and operated as a one-of-a-kind shore bombardment ship until its decommissioning in 2017.36 Similar full-scale prototyping has also been observed in Chinese ground and air systems. As one example, the Shenyang J-31/FC-31 stealth fighter that first appeared in 2012 was a full-scale flying prototype not associated at that time with any military acquisition program.37

Israel: Achieving Maximum Innovation at the Lowest Cost

Israel is driven to be as efficient and cost-effective as possible in developing the advanced military capabilities it needs.38 Despite its small size and scarce resources, Israel has for decades been committed to a defense strategy that emphasizes both military technological advantage and self-sufficiency in military technologies.39 Three best practices contribute to much of its success in disruptive military innovation. These are the Israeli program for building an elite corps of military innovation leaders; the use of operational demonstrators as a key step in military R&D; and the maintenance of close relationships between the operational military, military R&D, and commercial technology communities.

Workforce Development: Talpiot. After Israel’s near defeat in the 1973 Yom Kippur War, the nation’s military leaders and academics determined they needed a highly trained body of technically educated military leaders to ensure the technological superiority of Israel’s forces. The program—called Talpiot, meaning “bastion” or “fortified tower” in Hebrew—was launched in 1979 as an elite training program to develop those leaders.40 Management of Talpiot was given to the new Administration for the Development of Weapons and Technological Infrastructure, known by its Hebrew acronym MAFAT, established by Defense Minister Ariel Sharon.41

Israeli citizens, both male and female, have a period of compulsory military service following high school. Instead of enlisting as conscripts, the highest scoring science, technology, engineering, and math (STEM) students can apply for admission to Talpiot to satisfy their service requirement. The selection is highly competitive, with only 30 to 60 applicants making the cut for each year’s class. Students are selected for not only STEM skills but also leadership aptitude and the ability to communicate and work as part of a team.42

After selection, they complete a structured military and technical training program, regarded as “like having a Rhodes scholarship, a presidential fellowship, and a Harvard MBA all rolled into one.”43 The cadets attend classes at Hebrew University, taking a rigorous but broad curriculum of math, physics, and engineering courses designed to give them the tools to address many types of technical problems.44 They also conduct lead-in training with multiple military units from all branches of the Israel Defense Forces (IDF).45 It is not unusual for a Talpiot graduate (known as “a Talpiot”) to have attended airborne school, learned to operate a tank, gone to sea on a naval vessel, and trained in simulators with an air force flying unit. They experience the aggregate of the military training that different types of normal conscripts would receive.46 In addition, each student conducts a thesis project that proposes a technical solution to a military need that he or she identified during training. For example, the Trophy Active Defense System had its origin as a Talpiot project.47

During academic training, the cadets live together as a cohort, developing a tight network that serves them throughout their careers. Because of their cross-service military training, they also develop a network across military branches and units.

Talpiots serve for six or more years following commissioning as officers. Many extend their academic training, going on to earn specialized master’s or doctoral degrees. They are then assigned individually to different military units or R&D organizations. The active-duty assignments for each Talpiot are carefully selected by MAFAT to match his or her skills, training, and interests, with many Talpiots serving initially in programs or units related to their thesis topics.48

In service, the Talpiots serve as an elite corps of technically trained military officers who act as the glue between Israel’s operational military and defense technology communities. They have a firsthand understanding of both the military requirements in the field and the applicable science and technology and are expected to take the initiative to use both to identify and solve problems.

Talpiot graduates who stay in the military beyond their service commitment tend to be promoted and often end up in senior leadership positions.49 Many, however, are recruited by the private sector, where they are highly sought for technical and management positions. The program is perceived as a breeding ground for Israel’s tech industry CEOs, as a long list of technology corporations and startups are led by former Talpiots.50 This elite reputation, in turn, further drives the top high school candidates in the country to apply for the program. The key success factors for the Talpiot program can be summarized as follows:51

- rigorous and multidimensional selection process

- unique combination of military and academic training with emphasis on the big picture

- careful matching of graduates with follow-on assignments

- popular perception as a path to elite career opportunities.

Operational Demonstrators. Israel’s need for efficiency in military development means it cannot afford to let potentially impactful advances languish in the “valley of death” between invention and adoption. Thus, operational demonstrator experiments are used by MAFAT as a key step on the military innovation pathway. They are particularly important for disruptive bottom-up innovations for which formal requirements may not yet exist.52

Because Israel does not operate any government defense laboratories, all new technologies are developed by industry. MAFAT funding supports the development of new military technologies from the basic research through operational demonstrator steps. In the operational demonstrator step, working prototypes of new technologies are provided to active military units for evaluation in the field. Feedback from the operational demonstrator period is valuable, both in fine-tuning the technology to meet military needs and in developing military support for the new technology.

Because the operational demonstrators are conducted as part of R&D, and not part of a military acquisition program, they have freedom to move quickly and the ability to take risk. The applicable military branch is involved early in the demonstrator process but in terms of resources is usually responsible only for designating the participating military unit. Funding is budgeted by thrust area, not by individual demonstrator project, so MAFAT has the flexibility to allocate or reallocate funds between demonstrators as opportunities arise.53 This allows for dozens of operational demonstrators to be conducted each year.

Prototype technologies are usually provided to units in training, but because the IDF are often involved in action, sometimes unexpectedly, the technology often receives early combat experience. This was the case with the first Iron Dome antimissile batteries, two of which were deployed as demonstrator-phase prototypes to the towns of Beersheba and Ashkelon near the Gaza Strip after Hamas began a rocket offensive in March 2011.54 Real-life missile engagement experience helped refine the system. Perhaps more important, the visible successes of the prototypes won IDF support for the technology. Following successful missile interceptions, the previously skeptical commander of the Israeli air force met the project leader in Ashkelon and announced, “You now have the biggest supporter you’ll ever have! I was wrong when I didn’t believe!”55

In another example, the Trophy Active Defense System for the Merkava Mark 4 tank was first tested as a demonstrator during the 10-day IDF Joint Combat exercise in October 2010.56 Recently, a computerized smart gunsight for infantry rifles also received an operational demonstrator evaluation during IDF infantry training. When inexperienced recruits were able to hit moving targets with the first bullet with more than 70 percent accuracy, the dramatic results led to an initial defense ministry order of 2,000 gunsights.57

Operational Military/R&D/Industry Collaboration. Last, the Israeli defense innovation system places significant emphasis on collaboration and the building of relationships and information linkages, both between the operational military and MAFAT and between the military’s R&D activities and the commercial sector.

At the top, MAFAT is headed by a three-star general equivalent who reports directly to both the IDF chief of staff and the director-general of the defense ministry. This makes MAFAT itself a bridge between the civilian and military halves of the Israeli defense enterprise.58 At the intermediate levels, MAFAT personnel have a close relationship with their operational military counterparts. Many MAFAT staff are uniformed military, including Talpiots. R&D working plans are routinely discussed with the military branches at the O4/O5 levels. Thus, operational needs are not communicated by reports—the R&D personnel often understand them almost as well as their operational counterparts.59 Operational leaders similarly have good awareness of the R&D pipeline.

Because most of the scientists, engineers, and executives in the Israeli tech industry are IDF reservists with prior military training, they are familiar with military needs.60 However, former military service is not the only source of close relationships between the military and private sector. The translation of military advances to commercial uses is regarded as a powerful source of entrepreneurial opportunity. As Prime Minister Benjamin Netanyahu has stated, “Applying military technology to the civilian sector has become Israel’s greatest source of wealth.”61 Intermediate- and junior-level officers in MAFAT interact often with industry counterparts and do most of the initial vetting of industry inventions. Young R&D officers are encouraged to spend one to two days per week visiting technology companies, particularly startups.62 Prototype purchases and operational demonstrations are driven largely by these interactions and are supported by fast and flexible contracting processes designed for engaging commercial firms.63

Reaping the Benefits for U.S. Military Innovation

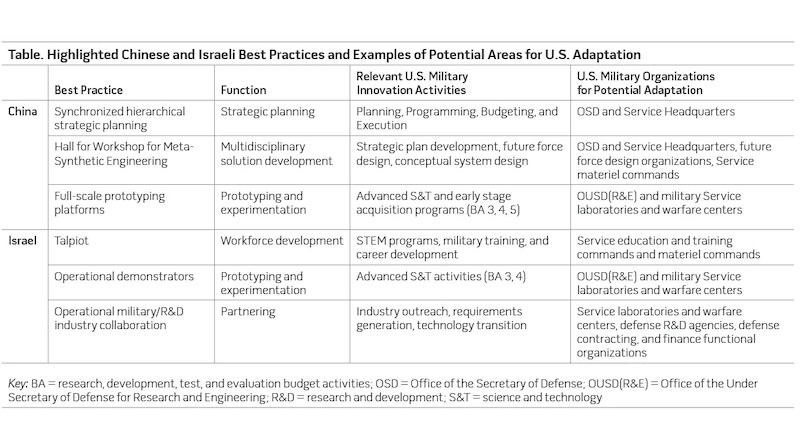

The six highlighted peer-country military innovation best practices suggest actionable options by which the U.S. defense innovation enterprise could accelerate disruptive innovation. The practices could benefit several areas. The table summarizes the practices and provides examples of the innovation activities and organizations that might benefit from adapting them for U.S. needs.

Strategic Planning and Future Force Design. Strategic planning is less synchronized in the U.S. system than in China’s. The National Defense Strategy (formerly the Quadrennial Defense Review) is produced approximately every 4 years. Other long-range technology forecasting studies and future force design studies within the Office of the Secretary of Defense and the military Services occur on less regular schedules and are often one of a kind. Rarely is there a long-range (that is, beyond a 5-year budget horizon), multi-Service integrated treatment of future defense strategy, weapons system development needs, and enabling S&T priorities, as produced regularly by the Chinese planning process.

One consequence of not having a long-range strategy is that potentially disruptive U.S. technological innovations, such as unmanned aircraft and stealth technology, sometimes have had to fight an uphill battle against nearer term priorities.64 Disruptive technologies are challenging to embrace. An authoritative “demand signal” that mandates a longer term perspective and the adoption of leap-ahead capabilities for the benefit of the future force could greatly speed the process of institutional adoption for disruptive innovations.

In addition, in the DOD planning, programming, budgeting, and execution system, it can be challenging to secure the resources to adopt future innovations that may not yet exist. Adapting the Chinese practice of applying a generation-based framework to future technologies could help overcome this. In the Chinese framework, the programs and funding for implementing upcoming technology generations can be effectively preprogrammed as placeholders, and the only question is which specific technologies will be selected. The commercial semiconductor industry uses a similar framework in the form of a roadmap that projects the future dates of industry-wide transitions to smaller microelectronic feature sizes.65 By synchronizing their R&D plans with the common roadmap, firms across the industry can develop next-generation manufacturing technology in the likelihood that the necessary complementary technologies, and the demand from manufacturers, will arrive at the same time. This helps the entire industry make rapid leaps forward.

U.S. defense planners are increasingly challenged to make rigorous and defensible plans covering large mission spaces involving complex emerging technologies. For instance, the Missile Defense Review released in January 2019 was the result of almost 2 years of work but was nonetheless unable to converge on definitive recommendations in 11 major areas.66 A more powerful methodology for addressing such complex problems involving many quantitative and qualitative factors could be beneficial. A methodology similar to the HWMSE, which could leverage modern information technology to help converge giant sets of data and expert judgment, could help tackle many such challenges.

The U.S. system benefits from flexibility. The full Chinese system of defense planning would not be appropriate for the United States. It may also prove too prescriptive for China if the country fully catches up with the United States, requiring it to invent new military technologies instead of acting as a “fast follower.” However, adapting just enough of the Chinese planning process to provide a coordinated long-range technology-planning framework that would be built around placeholders instead of specific technologies and designed using suitably powerful modern planning methodologies could address many of the coordination challenges that slow U.S. disruptive military innovation.

Prototyping and Experimentation. U.S. military acquisition policy encourages the use of prototyping and experimentation, but the resources to enable it, and its embrace as a critical step in military innovation, may be less robust than in the two peer countries.

Revisiting the example of naval prototyping and experimentation, there are some dedicated R&D testbed vessels in the United States, such as the 61-ton Stiletto that is funded by the Office of the Assistant Secretary of Defense for Research and Engineering.67 But most full-scale at-sea prototyping and demonstration relies on operational combat vessels. Opportunities are limited because of the disruption to operational ships and missions. It also can be expensive. For example, the Naval Surface Warfare Center conducted an at-sea full-scale trial of a developmental low-cost sensor system. The sensor system cost $375,000, but it cost $7.5 million to modify an Arleigh Burke–class destroyer to install the system and another $7.5 million after the experiments were completed to restore the vessel to its baseline configuration.68 Provision of more full-scale platforms dedicated to prototyping and experimentation, as in Chinese military practice, could reduce the time and cost to conduct such activities. In past periods of rapid innovation, the U.S. military lavished greater resources on such activities. For example, following World War II, the Marine Corps created an entire experimental flying unit, HMX-1, to explore the technical and operational potential of the newly emerging helicopters as military platforms.69

Several U.S. programs help put emerging technologies in the hands of military personnel for evaluation in the field, such as the Army Expeditionary Warrior Experiment.70 However, taking prototype technologies from military R&D programs and putting them through field experiments that are totally supported by R&D funds is not standard practice as it is in Israel. Almost all the Advanced Component Development and Prototyping funding in the U.S. system is controlled by major acquisition programs. Considering the important role that operational demonstrators play in accelerating Israeli military innovation, an analogous R&D-focused practice in the United States could greatly speed disruptive innovations to the warfighter.

Cross-Sector Collaboration and Talent Development. Military technology leaders in the United States have sometimes dreamed of a situation in which the top talent in Silicon Valley dedicate themselves to military innovation for the benefit of the country’s defense. That situation is the norm in Israel. The Talpiot program routes the country’s rising technical and entrepreneurial stars through service in military R&D by offering a remarkable educational opportunity and a place in a cohort of elite future military and business leaders. Although the United States does not have the requirement of universal military service to route its young people into uniform, it has a vastly larger pool of talent from which to draw. Similarly, prestigious and selective cohorts, such as the astronaut corps, continue to attract patriotic-minded and highly talented American youth to STEM studies and government service. Adapting some of the success factors of the Talpiot program could deliver a new pipeline of innovation change agents to the U.S. military and potentially inspire a greater interest in solving military problems among the Nation’s high-tech workforce. The Reserve Individual Mobilization Augmentee program and other existing mechanisms could help provide starting points for experimentation.

Close collaboration between private-sector innovators and forward-thinking military members has been an important ingredient in many past disruptive military technological advancements. The Israeli example suggests simple ways this culture of collaboration can be invigorated. Relatively modest reforms to encourage open lines of communication with industry peers outside of formal source selections, in particular at the more junior grades, could yield great benefits. These could be synergistic with, and help capitalize on, commercially friendly reforms to U.S. defense R&D contracting and rapid acquisition practices that are already under way.

Every practice must be adapted and tailored to the environment in which it is applied. The effective military innovation systems of China and Israel exhibit at least six transferable best practices that could be adapted and applied to accelerate U.S. disruptive military innovation. Such constructive adaptation could help the United States recapture its advantage in innovation, as when U.S. manufacturers recaptured their competitiveness in the 1990s by adapting the key practices that enabled the rapid gains by Japanese industry. Looming technological revolutions in areas such as artificial intelligence, autonomy, directed energy, quantum science, and elsewhere make it imperative for the United States to lead in converting emerging technologies into new military capabilities. The options defined here may help inform ongoing changes to U.S. military R&D operational practices and help secure the technological advantage needed to achieve the goals of the National Defense Strategy.

*About the author: Colonel George M. Dougherty, USAF, Ph.D., is the Individual Mobilization Augmentee to the Deputy Assistant Secretary of the Air Force for Science, Technology, and Engineering, Office of the Assistant Secretary of the Air Force for Acquisition and Logistics, Washington, DC.

Source: This article was published in Joint Force Quarterly 98, which is published by the National Defense University.

Notes

1 Kari Hawkins, “AMC-Developed Weapon Systems Remain Vital to the Army,” Army, September 6, 2012, available at <www.army.mil/article/86839/AMC_developed_weapons_remain_vital_to_Army/>.

2 Summary of the 2018 National Defense Strategy of the United States of America: Sharpening the American Military’s Competitive Edge (Washington, DC: Department of Defense, 2018), available at <https://dod.defense.gov/Portals/1/Documents/pubs/2018-National-Defense-Strategy-Summary.pdf>.

3 Dennis J. Blasko, “‘Technology Determines Tactics’: The Relationship Between Technology and Doctrine in Chinese Military Thinking,” Journal of Strategic Studies 34, no. 3 (June 2011), 355–382.

4 Jim Garamone, “U.S. Must Act Now to Maintain Military Technological Advantage, Vice Chairman Says,” DOD News, June 21, 2018, available at <https://dod.defense.gov/News/Article/Article/1557052/us-must-act-now-to-maintain-military-technological-advantage-vice-chairman-says/>.

5 Science and Technology Strategy: Strengthening USAF Science and Technology for 2030 and Beyond (Washington, DC: Headquarters Department of the Air Force, April 2019).

6 George M. Dougherty, “Promoting Disruptive Military Innovation: Best Practices for DOD Experimentation and Prototyping Programs,” Defense Acquisition Research Journal 25, no. 1 (January 2018), 2–29, available at <www.dau.edu/library/arj/ARJ/arj84/ARJ84%20Article%201%20-%2017-782%20Dougherty.pdf>.

7 “What Does China Really Spend on Its Military?” China Power Project, Center for Strategic and International Studies, December 28, 2015, available at <https://chinapower.csis.org/military-spending/>.

8 Tai Ming Cheung, “How China’s Defense Innovation System Is Advancing the Country’s Military Technological Rise,” Study of Innovation and Technology in China (SITC) Research Brief, Series 10 (May 3, 2018), available at <https://escholarship.org/uc/item/7c75995r>.

9 Tai Ming Cheung, Eric Anderson, and Fan Yang, “Chinese Defense Industry Reforms and Their Implications for U.S.-China Military Technological Competition,” SITC Research Brief, Series 9 (January 4, 2017), available at <https://escholarship.org/uc/item/84v3d66k>.

10 Tai Ming Cheung, “An Uncertain Transition: Regulatory Reform and Industrial Innovation in China’s Defense Research, Development, and Acquisition System,” in Forging China’s Military Might: A New Framework for Assessing Innovation, ed. Tai Ming Cheung (Baltimore: Johns Hopkins University Press, 2014), 47–65; Cheung, Anderson, and Yang, “Chinese Defense Industry Reforms.”

11 Tai Ming Cheung, “U.S.-China Military Technological Competition and the Making of Chinese Weapons Development Strategies and Plans,” SITC Research Brief, Series 9 (January 2, 2017), available at <https://escholarship.org/uc/item/43m5m3gp>; Eric Hagt, “The General Armament Department’s Science and Technology Committee: PLA-Industry Relations and Implications for Defense Innovation,” in Forging China’s Military Might, 66–86; Andrew L. Ross, “Framing Chinese Military Innovation,” in China’s Emergence as a Defense Technological Power, ed. Tai Ming Cheung (Abingdon-on-Thames, UK: Routledge, 2013), 187–213.

12 Jon Grevatt, “China Plans Major Restructure of Military R&D Infrastructure,” Jane’s Defence Industry (July 13, 2017).

13 Andrea Gilli and Mauro Gilli, “Why China Has Not Caught Up Yet: Military-Technological Superiority and the Limits of Imitation, Reverse Engineering, and Cyber Espionage,” International Security 43, no. 3 (Winter 2018–2019), 141–189.

14 Tai Ming Cheung et al., Planning for Innovation: Understanding China’s Plans for Technological, Energy, Industrial, and Defense Development (San Diego, CA: University of California Institute on Global Conflict and Cooperation, July 28, 2016), available at <https://www.uscc.gov/research/planning-innovation-understanding-chinas-plans-technological-energy-industrial-and-defense>.

15 Cheung, “U.S.-China Military Technological Competition.”

16 Cheung et al., Planning for Innovation, 20.

17 Ibid., 21.

18 Tai Ming Cheung, Innovation in China’s Defense Research, Development and Acquisition System, SITC Policy Brief 20, 2011, available at <https://escholarship.org/uc/item/43v5v0nt>.

19 Ibid.

20 Hagt, “The General Armament Department’s Science and Technology Committee.”

21 Ibid.

22 Cheung et al., Planning for Innovation, 23.

23 Ibid., 23–24.

24 Sun Hong and Li Lin, “On the Modes of Advancing Weapons and Equipment Development with Chinese Characteristics,” China Military Science 6 (2005), 55–60.

25 Qian Xuesen, Yu Jingyuan, and Dai Ruwei, “A New Discipline of Science—The Study of Open Complex Giant System and Its Methodology,” Chinese Journal of Systems Engineering and Electronics 4, no. 2 (1993), 212.

26 Jifa Gu, “The Meta-Synthesis System Approach,” in Knowledge Synthesis: Western and Eastern Cultural Perspectives, ed. Yoshiteru Nakamori (Tokyo: Springer Japan, 2016), 55–78.

27 Ibid.

28 Fu Xin Hua, “Hall for Workshop of Meta-Synthetic Engineering for the Demonstration of Airborne Equipment Development,” Proceedings of the Fourth International Conference on Mechatronics, Materials, Chemistry, and Computer Engineering 2015, Xian, China, December 2015.

29 Gu, “The Meta-Synthesis System Approach”; Xijin Tang, “Problem Structuring Process by Qualitative Meta-Synthesis Technologies,” in Knowledge Synthesis: Western and Eastern Cultural Perspectives, 79–105.

30 Tang, “Problem Structuring Process.”

31 Ma Kuan, Gong Maohua, and Zhou Shaopeng, “Application of Technology Maturity in Management of National Defense Equipment Research and Development Program: A Case of an Aerospace Project,” National Defense Science and Technology 37, no. 2 (2016), 73–77.

32 Stephen Saunders, IHS Jane’s Fighting Ships 2016–2017 (Bracknell, UK: IHS Global Ltd., 2016), 161.

33 James C. Bussert, “China Employs Ships as Weapon Test Platforms,” Signal Magazine, March 1, 2013, available at <www.afcea.org/content/?q=china-employs-ships-weapon-test-platforms>.

34 Saunders, IHS Jane’s Fighting Ships 2016–2017, 138.

35 David Axe, “China’s Navy Railgun Is Out for Sea Trials. Here’s Why It’s a Threat to the U.S. Navy,” The National Interest, January 6, 2019, available at <https://nationalinterest.org/blog/buzz/chinas-navy-railgun-out-sea-trials-heres-why-it’s-threat-us-navy-40812>.

36 “Chinese Fire Support Frigate,” Navy Matters, June 16, 2017, available at <https://navy-matters.blogspot.com/2017/06/chinese-fire-support-frigate.html>.

37 Bradley Perrett and Steve Trimble, “Avic’s J-31 Fighter Is a Winner After All,” Aviation Week and Space Technology, November 9, 2018, available at <https://aviationweek.com/defense/avic-s-j-31-fighter-winner-after-all>.

38 Dmitry Adamsky, “The Israeli Approach to Defense Innovation,” SITC Research Brief, Series 10 (May 8, 2018), available at <https://escholarship.org/uc/item/4t07267h>.

39 Kobi Kagan et al., “Defense Structure, Procurement, and Industry: The Case of Israel,” in Defense Procurement and Industry Policy: A Small Country Perspective, ed. Stefan Markowski, Peter Hall, and Robert Wylie (London: Routledge, 2010), 228–254.

40 Abigail Klein Leichman, “The IDF Incubator for Israel’s Future CEOs,” Israel 21c, September 19, 2012, available at <www.israel21c.org/the-idf-incubator-for-israels-future-ceos/>.

41 Jason Gewirtz, Israel’s Edge: The Story of the IDF’s Most Elite Unit—Talpiot (Jerusalem: Gefen, 2016), 35–36.

42 Ibid., 46–47; Leichman, “The IDF Incubator.”

43 Richard Rapaport, “Beating Swords into IPO Shares,” Forbes, June 1, 1998, 92–102.

44 Leichman, “The IDF Incubator.”

45 Gewirtz, Israel’s Edge, 80–81.

46 Ibid., 81.

47 Ibid., 64, 80.

48 Ibid., 47.

49 Amir Geva, Israeli Defense R&D attaché, interview by author, June 4, 2018.

50 Leichman, “The IDF Incubator.”

51 Gewirtz, Israel’s Edge, 47.

52 Geva, interview, June 4, 2018.

53 Ibid.

54 Amos Harel, “Israel to Invest $1 Billion in Iron Dome Missile Defense System,” Haaretz, May 9, 2011, 123–124.

55 Dan Raviv, “Inside the Iron Dome,” Momentmag, July 17, 2018, available at <www.momentmag.com/inside-the-iron-dome/>.

56 “Merkava Mark 4 With ‘Trophy’ (Meil Ruach) Active Tank Defense System to Be Presented in Joint Combat Exercise Demonstration for First Time,” Israel Defense Forces, October 11, 2010, available at <https://idfspokesperson.wordpress.com/2010/10/11/merkava-mark-4-with-trophy-meil-ruach-active-tank-defense-system-to-be-used-in-joint-combat-exercise-demonstration-for-first-time-12-oct-2010/>.

57 Udi Etzion, “IDF Shooters Get ‘Smart’ Gun Sight to Increase Accuracy,” Ynet News, January 13, 2019, available at <www.ynetnews.com/articles/0,7340,L-5444185,00.html>.

58 Geva, interview, June 4, 2018.

59 Ibid.

60 Kagan et al., “Defense Structure, Procurement, and Industry.”

61 Rapaport, “Beating Swords into IPO Shares.”

62 Geva, interview, June 4, 2018.

63 Amir Geva, Israeli Defense R&D attaché, interview by author, January 27, 2019.

64 Dougherty, “Promoting Disruptive Military Innovation.”

65 W.J. Spencer and T.E. Seidel, “International Technology Roadmaps: The U.S. Semiconductor Experience,” in Productivity and Cyclicality in Semiconductors: Trends, Implications, and Questions, ed. Dale W. Jorgenson and Charles W. Wessner (Washington, DC: National Academies Press, 2004), 135–150.

66 Aaron Mehta, “The Next Six Months Could Define America’s Missile Defense for a Generation,” Defense News, January 27, 2019, available at <www.defensenews.com/space/2019/01/28/the-next-six-months-could-define-americas-missile-defense-for-a-generation/>.

67 Saunders, IHS Jane’s Fighting Ships 2016–2017, 959.

68 Gary Shields, director of the Disruptive Technologies Laboratory, Naval Surface Warfare Center, Carderock Division, interview by author, June 1, 2018.

69 Chuck Lloyd and Rick Llinares, “HMX-1: ‘The First and Finest,’” Naval Aviation News (May–June 1997), 11–19.

70 Dougherty, “Promoting Disruptive Military Innovation.”

You remarked “Israel’s near defeat” in the 1973 Yom Kippur War. I object to that assertion as its untrue and not a historial fact. I admit it did take a battering in the first 3 to 4 days, but thereafter recovered very well and eventually crossed the Sues Canal, occupied a big chunk of territory on the east bank , surrounded the starving Egyptian 3rd Army, and in easy range of Cairo. Equally Syria lost several hundred latest Russian tanks and even more land on the Golan Heights. Damascus came within 40km of Israeli artillery. After the Russians began resupply just after the war started the US began the same to Israel on 18 October 1973 when the war was already at its closing stages on both fronts.

I hope this helps your readers.