ITER: The Way To New Energy – Analysis

ITER (“The Way” in Latin) is one of the most ambitious energy projects in the world today. In southern France, 35 nations are collaborating to build the world’s largest tokamak, a magnetic fusion device that has been designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy based on the same principle that powers our Sun and stars. The experimental campaign that will be carried out at ITER is crucial to advancing fusion science and preparing the way for the fusion power plants of tomorrow.

France is ready to get the world’s most powerful magnet, which will kick off the ambitious ITER project aimed at demonstrating the working of a fusion reactor for commercial use. In 1985, the Soviet Union suggested building a next generation tokamak with Europe, Japan and the USA. Collaboration was established under the auspices of the International Atomic Energy Agency (IAEA). Scientists have been able to put together a plan for a fusion nuclear reactor over the years. It’s called the International Thermonuclear Experimental Reactor (ITER). ITER is an international fusion energy experiment where engineers and physicists will attempt to create a self-sustained fusion reaction for long durations. Between 1988 and 1990, the initial designs were drawn up for an International Thermonuclear Experimental Reactor (ITER- which also means ‘a path’ or ‘journey’ in Latin) with the aim of proving that fusion could produce useful energy. The four parties agreed in 1992 to collaborate further on engineering design activities for ITER. Canada and Kazakhstan are also involved through Euratom and Russia, respectively.

Though ITER project began in 1985, however the first experimental run was repeatedly delayed. It is expected to be operational in 2035, according to the present timeline. The reactor is currently undergoing a machine assembly phase. Over ten million components must be transported, assembled, and integrated from the seven-member countries where they were created and tested. It will be a technology demonstration machine that will allow the creation of futuristic fusion devices that can function in the same manner as today’s fission reactors. After ITER is operational, the deployment of fusion energy for electricity generation for our daily requirements may take a few decades longer. Coming up in France, scientists aim to test the integrated technologies, materials, and physics needed for the commercial production of fusion-based electricity. The project has China, the European Union, India, Japan, Korea, Russia and the United States engaged in a 35-year collaboration to build and operate the ITER experimental device.

To produce the massive amount of energy, a small amount of deuterium and tritium (hydrogen) gas is injected into a large, doughnut-shaped vacuum chamber, called a tokamak. The hydrogen is then heated until it becomes ionized plasma that is confined by giant superconducting magnets like the Central Solenoid. The hydrogen plasma, when heated up to 150 million degrees Celsius ten times hotter than the core of the Sun, fusion energy is created.

Six years later, the ITER Council approved the first comprehensive design of a fusion reactor based on well-established physics and technology with a price tag of $6 billion. But, the USA then decided to pull out of the project, forcing a 50 percent reduction in costs and a redesign. The result was the ITER Fusion Energy Advanced Tokomak (ITER-FEAT) – initially expected to cost $3 billion but still achieve the targets of a self-sustaining reaction and a net energy gain. The envisaged energy gain is unlikely to be enough for a power plant, but it should demonstrate feasibility.

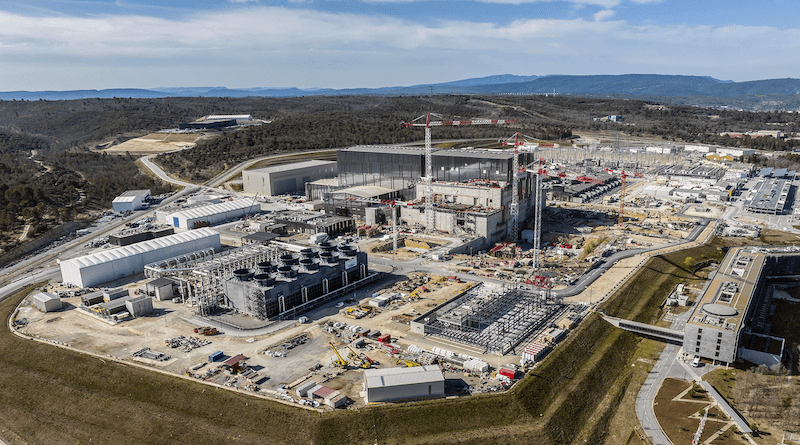

In 2003, the USA rejoined the project and China also announced it would join. After deadlocked discussion, the six partners agreed in mid-2005 to site ITER at Cadarache, in southern France. The deal involved major concessions to Japan, which had put forward Rokkasho as a preferred site. The European Union (EU) and France would contribute half of the then estimated €12.8 billion total cost, with the other partners – Japan, China, South Korea, USA and Russia – putting in 10 percent each. Japan will provide a lot of the high-tech components, will host a €1 billion materials testing facility – the International Fusion Materials Irradiation Facility (IFMIF) – and will have the right to host a subsequent demonstration fusion reactor. India became the seventh member of the ITER consortium at the end of 2005. In November 2006, the seven members – China, India, Japan, Russia, South Korea, the USA and the European Union – signed the ITER implementing agreement. The total cost of the 500 MW ITER comprises about half for the ten-year construction and half for 20 years of operation.

Site preparation works at Cadarache commenced in January 2007. First concrete for the buildings was poured in December 2013. Experiments were due to begin in 2018, when hydrogen will be used to avoid activating the magnets, but this is now expected in 2025. The first D-T plasma is not expected until 2035. ITER is large because confinement time increases with the cube of machine size. The vacuum vessel will be 19 m across and 11 m high, and weigh more than 5000 tonnes.

The goal of ITER is to operate with a plasma thermal output of 500 MW (for at least 400 seconds continuously) with less than 50 MW of plasma heating power input. No electricity will be generated at ITER.

An associated CEA facility at Cadarache is WEST, formerly Tore Supra, which is designed to test prototype components and accelerate their development for ITER. It is focused on the divertor structure to remove helium, testing the durability of tungsten materials used.

A 2 GW Demonstration Power Plant, known as Demo, is expected to demonstrate large-scale production of electrical power on a continual basis. Initially, the conceptual design of Demo was expected to be completed by 2017, with construction beginning around 2024 and the first phase of operation commencing from 2033. It has since been delayed, with construction now planned for after 2040.

TECHNICAL DESIGN

Vacuum Vessel

The vacuum vessel is the central part of the ITER machine: a double-walled steel container in which the plasma is contained by means of magnetic fields. It will be twice as large and 16 times as heavy as any previously manufactured fusion vessel: each of the nine torus-shaped sectors will weigh approximately 450 tonnes. When all the shielding and port structures are included, this adds up to a total of 5,116 tonnes. Its external diameter will measure 19.4 metres (64 ft), the internal 6.5 metres (21 ft). Once assembled, the whole structure will be 11.3 metres (37 ft) high.

The primary function of the vacuum vessel is to provide a hermetically sealed plasma container. Its main components are the main vessel, the port structures and the supporting system. The main vessel is a double-walled structure with poloidal and toroidal stiffening ribs between 60-millimetre-thick (2.4 in) shells to reinforce the vessel structure. These ribs also form the flow passages for the cooling water. The space between the double walls will be filled with shield structures made of stainless steel. The inner surfaces of the vessel will act as the interface with breeder modules containing the breeder blanket component. These modules will provide shielding from the high-energy neutrons produced by the fusion reactions and some will also be used for tritium breeding concepts.

The vacuum vessel has a total of 44 openings that are known as ports – 18 upper, 17 equatorial, and 9 lower ports – that will be used for remote handling operations, diagnostic systems, neutral beam injections and vacuum pumping. Remote handling is made necessary by the radioactive interior of the reactor following a shutdown, which is caused by neutron bombardment during operation.

Vacuum pumping will be done before the start of fusion reactions to create the necessary low density environment, which is about one million times lower than the density of air.

Breeder Blanket

ITER will use a deuterium-tritium fuel. While deuterium is abundant in nature, tritium is much rarer because it is a hydrogen isotope with a half-life of just 12.3 years and there is only approximately 3.5 kilograms of natural tritium on earth. Owing to this limited terrestrial supply of tritium, a key component of the ITER reactor design is the breeding blanket. This component, located adjacent to the vacuum vessel, serves to produce tritium through reaction with neutrons from the plasma. There are several reactions that produce tritium within the blanket. Lithium-6 produces tritium via (n,t) reactions with moderated neutrons, while Lithium-7 produces tritium via interactions with higher energy neutrons via (n,nt) reactions.

Concepts for the breeder blanket include helium-cooled lithium lead (HCLL), helium-cooled pebble bed (HCPB), and water-cooled lithium lead (WCLL) methods. Six different tritium breeding systems, known as Test Blanket Modules (TBM), will be tested in ITER and will share a common box geometry. Materials for use as breeder pebbles in the HCPB concept include lithium meta-titanate and lithium orthosilicate. Requirements of breeder materials include good tritium production and extraction, mechanical stability and low levels of radioactive activation.[

Magnet System

ITER is based on magnetic confinement fusion that uses magnetic fields to contain the fusion fuel in plasma form. The magnet system used in the ITER tokamak will be the largest superconducting magnet system ever built. The system will use four types of magnets to achieve plasma confinement: a central solenoid magnet, poloidal magnets, toroidal-field coils, and correction coils. The central solenoid coil will be 18 meters tall, 4.3 meters wide, and weigh 1000 tonnes. It will use superconducting niobium-tin to carry 45 kA and produce a peak field of more than 13 teslas.

The 18 toroidal field coils will also use niobium-tin. They are the most powerful superconductive magnets ever designed with a nominal peak field strength of 11.8 teslas and a stored magnetic energy of 41 gigajoules. Other lower field ITER magnets (poloidal field and correction coils) will use niobium-titanium for their superconducting elements.

Additional Heating

To achieve fusion, plasma particles must be heated to temperatures that reach as high as 150 million °C and to achieve these extreme temperatures multiple heating methods must be used. Within the tokamak itself, changing magnetic fields produce a heating effect but external heating is also required. There will be three types of external heating in ITER:

- Two one-million volt heating neutral beam injectors (HNB) that each will provide about 16.5MW to the burning plasma, with the possibility to add a third injector. The beams generate electrically charged deuterium ions that are accelerated through five grids to reach the required energy of 1MV and the beams can operate for the entire plasma pulse duration, a total of up to 3600 seconds. The prototype is being built at the Neutral Beam Test Facility (NBTF), which was constructed in Padua, Italy. There is also a smaller neutral beam that will be used for diagnostics to help detect the amount of helium ash inside the tokamak.[154]

- An ion cyclotron resonance heating (ICRH) system that will inject 20 MW of electromagnetic power into the plasma by using antennas to generate radio waves that have the same rate of oscillation as the ions in the plasma.

- An electron cyclotron resonance heating (ECRH) system that will heat electrons in the plasma using a high-intensity beam of electromagnetic radiation.

Cryostat

The ITER cryostat is a large 3,850-tonne stainless steel structure surrounding the vacuum vessel and the superconducting magnets, with the purpose of providing a super-cool vacuum environment.[157] Its thickness (ranging from 50 to 250 millimetres (2.0 to 9.8 in)) will allow it to withstand the stresses induced by atmospheric pressure acting on the enclosed volume of 8,500 cubic meters. On 9 June 2020, Larsen & Toubro completed the delivery and installation of the cryostat module. The cryostat is the major component of the tokamak complex, which sits on a seismically isolated base.

Divertor

The divertor is a device within the tokamak that allows for removal of waste and impurities from the plasma while the reactor is operating. At ITER, the divertor will extract heat and ash that are created by the fusion process, while also protecting the surrounding walls and reducing plasma contamination.

The ITER divertor, which has been compared to a massive ashtray, is made of 54 pieces of stainless-steel parts that are known as cassettes. Each cassette weighs roughly eight tonnes and measures 0.8 meters x 2.3 meters by 3.5 meters. The divertor design and construction is being overseen by the Fusion For Energy agency.

When the ITER tokamak is in operation, the plasma-facing units endure heat spikes as high as 20 megawatts per square metre which is more than four times higher than what is experienced by a spacecraft entering Earth’s atmosphere.

The testing of the divertor is being done at the ITER Divertor Test Facility (IDTF) in Russia. This facility was created at the Efremov Institute in Saint Petersburg as part of the ITER Procurement Arrangement that spreads design and manufacturing across the project’s member countries.

Cooling Systems

The ITER tokamak will use interconnected cooling systems to manage the heat generated during operation. Most of the heat will be removed by a primary water cooling loop, itself cooled by water from a secondary loop through a heat exchanger within the tokamak building’s secondary confinement. The secondary cooling loop will be cooled by a larger complex, comprising a cooling tower, a 5 km (3.1 mi) pipeline supplying water from the Canal de Provence, and basins that allow cooling water to be cooled and tested for chemical contamination and tritium before being released into the river Durance. This system will need to dissipate an average power of 450 MW during the tokamak’s operation.A liquid nitrogen system will provide a further 1300 kW of cooling to 80 K (−193.2 °C; −315.7 °F), and a liquid helium system will provide 75 kW of cooling to 4.5 K (−268.65 °C; −451.57 °F). The liquid helium system will be designed, manufactured, installed and commissioned by Air Liquide in France.

ITER Timeline

2005: Decision to site the project in France

2006: Signature of the ITER Agreement

2007: Formal creation of the ITER Organization

2007-2009: Land clearing and levelling

2010-2014: Ground support structure and seismic foundations for the Tokamak

2012: Nuclear licensing milestone: ITER becomes a Basic Nuclear Installation under French law

2014-2021: Construction of the Tokamak Building (access for assembly activities in 2019)

2010-2021: Construction of the ITER plant and auxiliary buildings for First Plasma

2008-2021: Manufacturing of principal First Plasma components

2015-2023: Largest components are transported along the ITER Itinerary

2020-2025: Main assembly phase I (dates according to the 2016 Baseline)

2022: Torus completion*

2024: Cryostat closure*

2024-2025: Integrated commissioning phase (commissioning by system starts several years earlier)*

Dec 2025: First Plasma*

2025-2035: Progressive ramp-up of the machine

2035: Deuterium-Tritium Operation begins

*These milestone dates (from the 2016 ITER Baseline) will be revised as part of an update to the ITER Baseline that is underway now. The Baseline Update will take into account the effects of technical challenges and the Covid-19 pandemic on the project schedule.

Throughout the ITER construction phase, the Council will closely monitor the performance of the ITER Organization and the Domestic Agencies through a series of high-level project milestones.

*Update 31 January 2021: In parallel with the Trade and Cooperation Agreement signed by the United Kingdom and the European Union on 24 December 2020, a Nuclear Cooperation Agreement (NCA) concluded between the UK and Euratom (the legal entity through which Europe holds its membership in ITER) makes clear the intent for the UK to remain a part of Fusion for Energy, the European Domestic Agency for ITER. In practical terms it means that the ITER Organization can expect the continued full involvement and participation of UK citizens and UK companies in ITER. The 35 nations participating in ITER are: the 27 European Union countries + (through Euratom) Switzerland and the United Kingdom + China, India, Japan, Korea, the Russian Federation, and the United States.

ITER-India

India’s contribution to ITER, dubbed ‘ITER-India’ is being run as a special project under IPR. It was in December 2005 that India became the full seventh member of ITER with a 10 per cent ‘in-kind’ contribution share out of a total of 150 distinct procurements. India’s Larsen & Toubro supplied the ITER’s cryostat, which is the world’s largest vacuum application stainless steel vessel. It weighs 3850 tonnes, with a height of 30m and a diameter of 30m. The cryostat was installed in 2020.

ITER-India is also responsible for supplying a number of other critical components and sub-systems, such as cryolines and a cryodistribution system for ITER’s cryoplants; in-wall shielding, which requires around 9000 blocks from 70,000 precision cut plates; a cooling water and heat rejection system; ICRF source system; diagnostic neutral beam system to detect He ash during the D-T phase of the ITER plasma; plasma diagnostics; power supplies for DNB, ICRF and ECRF systems; two gyrotron sources of 1MW power output at 170GHz for 3600s pulse length; X-ray crystal spectroscopy; electron cyclotron emission as well as various optical fibers, detectors, visible spectrometers and opto-mechanical components.

Participation in ITER has led to significant blanket and divertor technology development initiatives in India. In particular, identification of special materials that provide long life and low induced radioactivity in the extreme environments associated with tokamak operations has been emphasized. In fact, a Cu-Cr-Zr alloy with total impurity levels not exceeding 0.1 per cent has been developed as a back plate material for mounting PFCs used in ITER.

Alongside research into blanket materials there is also a thrust toward towards developing fusion fuel cycle and tritium systems. With India now confident of being able to scale up tokamak size, field strength, heating power and pulse length, the focus is inevitably shifting towards fusion reactor design, materials and remote handling. After all, the ultimate aim is to be able to build an optimized power generating reactor that is affordable, reliable and maintainable in a cost-effective manner.

The primary objective of ITER is the investigation and demonstration of burning plasmas—plasmas in which the energy of the helium nuclei produced by the fusion reactions is enough to maintain the temperature of the plasma, thereby reducing or eliminating the need for external heating. ITER will also test the availability and integration of technologies essential for a fusion reactor (such as superconducting magnets, remote maintenance, and systems to exhaust power from the plasma) and the validity of tritium breeding module concepts that would lead in a future reactor to tritium self-sufficiency.